Two Bin System Kanban

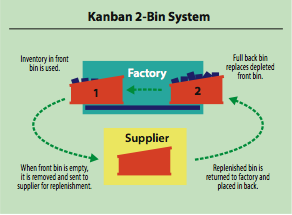

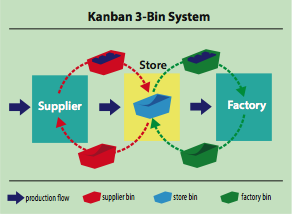

Two bin system kanban. Two bins with materials are placed on the factory floor. Typically the quantities in a Kanban Supermarket will be greater than. A two-bin system is the easiest way to implement a kanban system into a manufacturing or production facility.

Calculate the maximum inventory quantity for a given item based on daily usage and an inventory turnover goal. Firstly gathering information and planning is crucial for all items wishing to be stored in a Kanban system. The two bins system workes best when criterias are met which makes it more efficient.

Two bin system is old version of Kanban system. When Does the Two Bin System Work. A solid Kanban strategy has the ability to reduce stock-outs and.

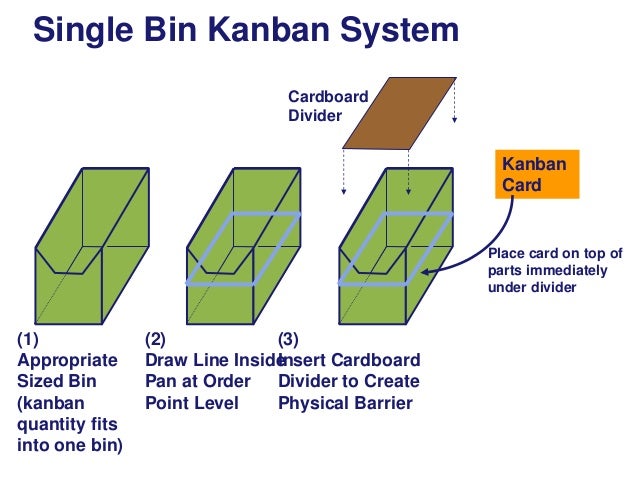

The Two Bin Kanban System is a simple yet highly effective way of maintaining enough stock of high consumption items near the production line. One of the most familiar tools used in Kanban manufacturing is called a 2 bin. The operations of the two processes are very similar.

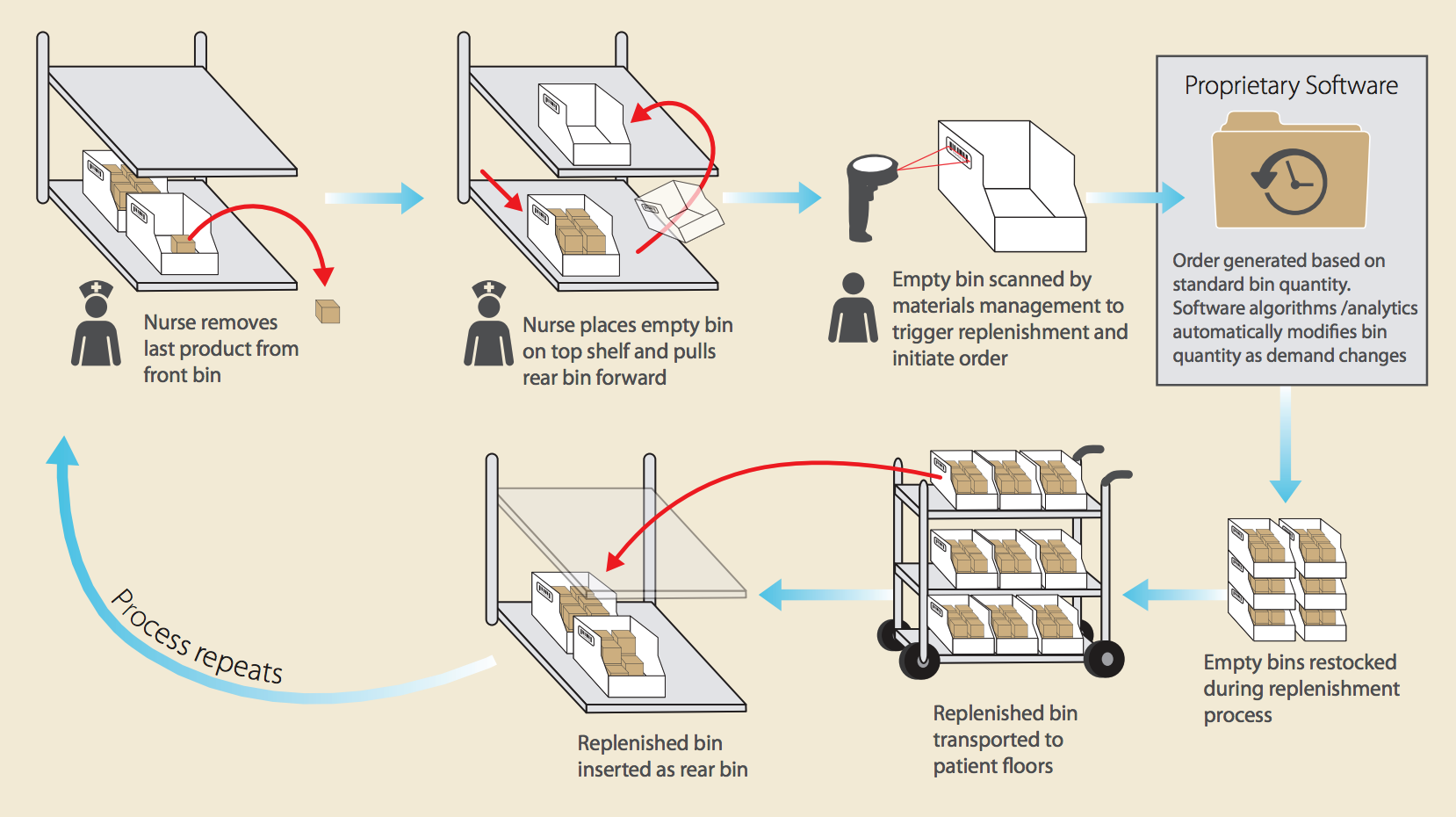

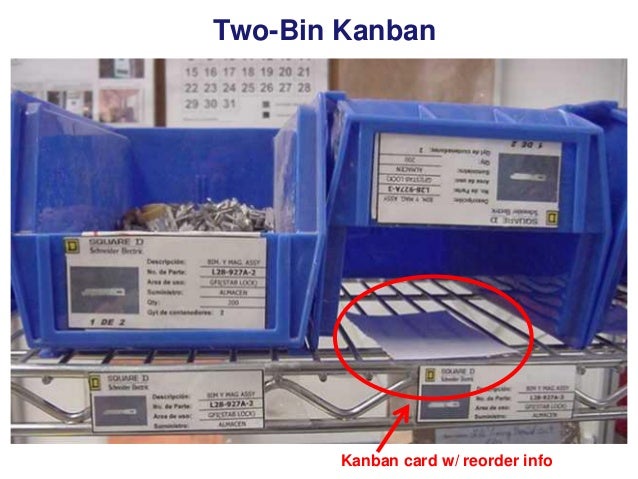

Materials manager came to explain the two-bin Kanban system to the nurses he got a round of applause which was quite frankly the first time Ive ever heard a materials manager get applause from nursing when they were describing a change in a system According to. Video explanation of two bin Kanbans About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features 2021 Google LLC. The two-bin Kanban system from the beginning is built on visual signs so that we can be immediately notified the moment part of our inventory is running low.

Kanban is a highly visual method for managing workflow inventory and more. This will give us time to replenish it and thus the production process wouldnt be delayed. For those that work in factories two containers are made available just for inventory.

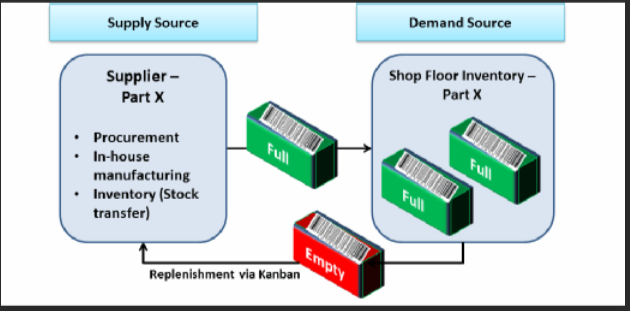

Kanban encourages the use of visual indicators to improve the flow and efficiency of production making it an ideal method for manufacturers of physical goods. The two-bin inventory control method is also sometimes referred to as kanban which is strongly associated with the just-in-time JIT method of a manufacturing process.

Kanban encourages the use of visual indicators to improve the flow and efficiency of production making it an ideal method for manufacturers of physical goods.

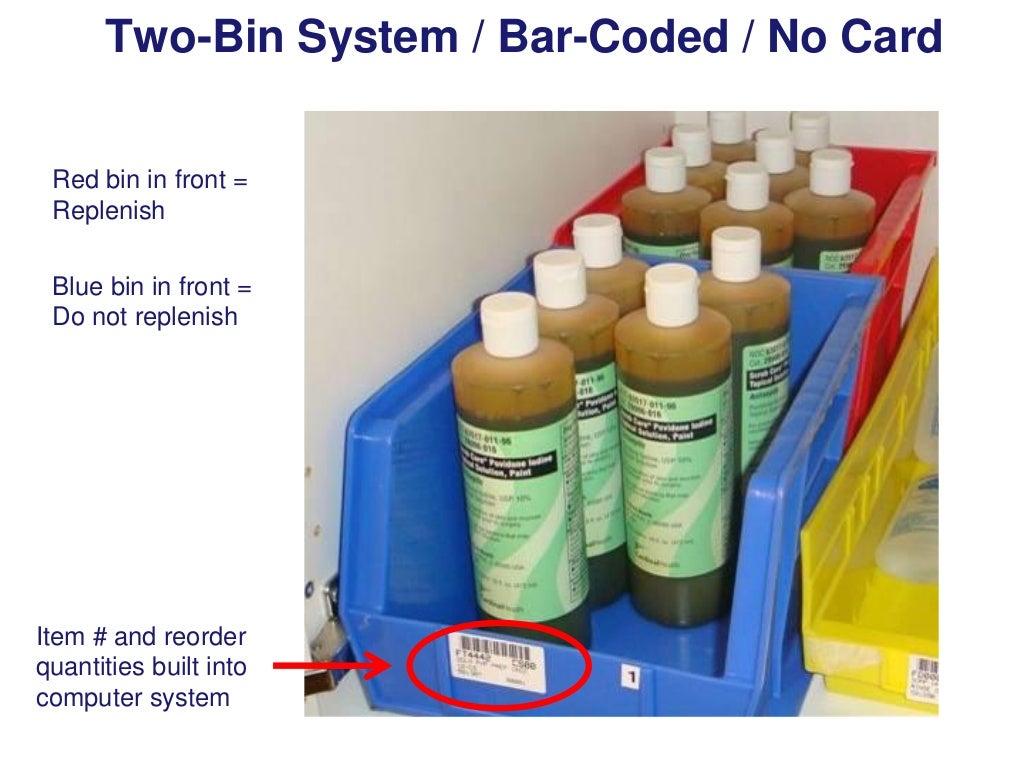

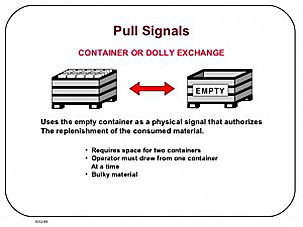

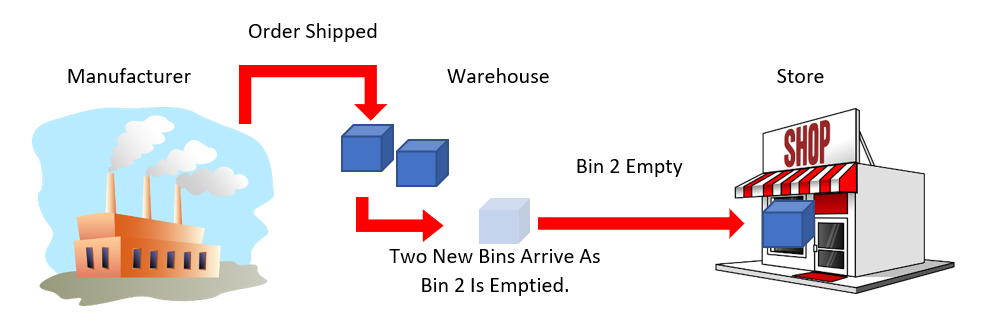

Two-Bin System Bar-Coded No Card Red bin in front Replenish Blue bin in front Do not replenish Item and reorder quantities built into computer system. The 2 bin system in its simplest form is discussed below with the steps The first bin is placed right ahead or top of the second bin. You can see our innovative two-bin Kanban system the TwinBin System here. Ad Solução completa para organizar e aumentar a produtividade da sua empresa. The two-bin system of reordering parts which often gets overlooked in our zeal to computerize everything. If the production line stops in a 2 Bin System then it should not be affecting the bin replineshment as the materials from the bin is already empty and the new material brought into will be kept in the place of the empty bin. How a 2 Bin Kanban System Works. Kanban is a lean manufacturing system of which the two-bin system is the most popular. Using a Kanban system to manage your inventory of low-cost production components can be a great way to improve lean manufacturing efforts and the two-bin method is one of the most common variations of this supply chain management strategy.

The 2 bin system is the way out to solve the above-discussed problems that are to maintain the right level of inventory. Typically the quantities in a Kanban Supermarket will be greater than. Materials manager came to explain the two-bin Kanban system to the nurses he got a round of applause which was quite frankly the first time Ive ever heard a materials manager get applause from nursing when they were describing a change in a system According to. The two bins system workes best when criterias are met which makes it more efficient. Video explanation of two bin Kanbans About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features 2021 Google LLC. When the first bin is empty this triggers a request for replenishment. Two-Bin Kanban Kanban card w reorder info.

Post a Comment for "Two Bin System Kanban"